L’utilisation de combustibles de substitution comme les pneumatiques usagés permet à nos cimenteries de réduire leur consommation de combustibles fossiles importés de pays souvent lointains, contribuant ainsi à réduire les émissions de gaz à effet de serre et à développer la transition énergétique sur nos territoires. Nous pouvons compter sur la réactivité et la fiabilité d’Aliapur pour livrer toute l’année des pneus broyés ou entiers répondant aux cahiers des charges des usines.

[Groupe cimentier international né en Isère, Vicat s'appuie sur 160 ans d'expérience. Le groupe compte près de 8000 collaborateurs répartis dans 11 pays. En 2018, a été créé Vicat Circulère : par la transformation des déchets de chantier et leur réincorporation dans des produits innovants et responsables, il s'agit de participer à un nouvel aménagement durable des espaces]

Breffni BOLZE

Chef de département Vicat CIRULère

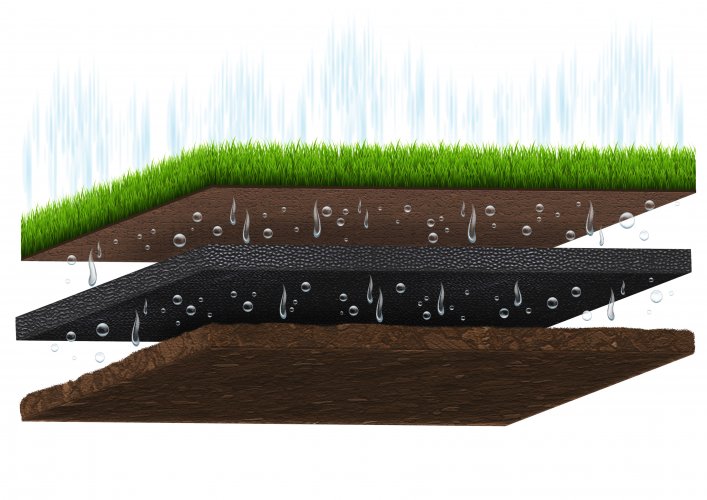

Lorsqu’en 2013, nous imaginons un « filtre-barrière contre la prolifération des moustiques » fabriqué avec du caoutchouc recyclé, solliciter l’expertise d’Aliapur s’impose. Le partage de ce projet avec Aliapur permettra l’identification des ressources et moyens nécessaires à mettre en œuvre dans les phases hydromécaniques, innocuité environnementale, faisabilité industrielle, analyse du marché. Ensemble nous avons construit une relation studieuse qui s’est transformée en en une collaboration de confiance, et ce, malgré une situation géographique particulière : Aliapur à Lyon et Aedes-system en Nouvelle-Calédonie. Dans ce parcours, nous avons particulièrement apprécié la qualité humaine de notre relation avec nos interlocuteurs « Aliapur » : leur disponibilité bien sûr, mais aussi et surtout, leur faculté à s’adapter à cette nouvelle voie de valorisation des Pneus Usagés qui affiche une forte image sanitaire et sociale.

Thierry SURIVI

Directeur général